Dielectric Protective Material (Covers and Radome Material)

Akita is developing a removable protective cover for the Navy AN/SPY-1 array radar in a Phase II SBIR (Small Business Innovation Research) effort. Currently, arrays are protected only by a thin layer of coated resin that is easily damaged by physical contact and provides virtually no mechanical protection from hail and other impacts. Such impacts can break the fragile ceramic RF windows, allowing seawater to enter the system where it blocks RF transmission and damages system components. This results in costly maintenance and downtime for critical national security assets. We are developing a removable, RF-transparent cover for the SPY-1 arrays that:

- Can be affixed to the array and remain secure in maritime conditions

- Can be removed and easily replaced if damaged

- Transmits the S-band RF energy used by the radar

- Provides improved environmental (water, UV, outdoor temperature range) and mechanical protection to the array

Additional potential uses of these covers and the material is protection of other array radars (such as the newer SPY-6 and other array radars used for target acquisition and missile guidance) and antennae and radomes used in air traffic control and weather radars and for protection of other outdoor RF antennae. Other possible applications are for automotive/self driving sensors. The Akita composite protective material addresses issues with cost, weight, and durability of existing RF-transparent materials.

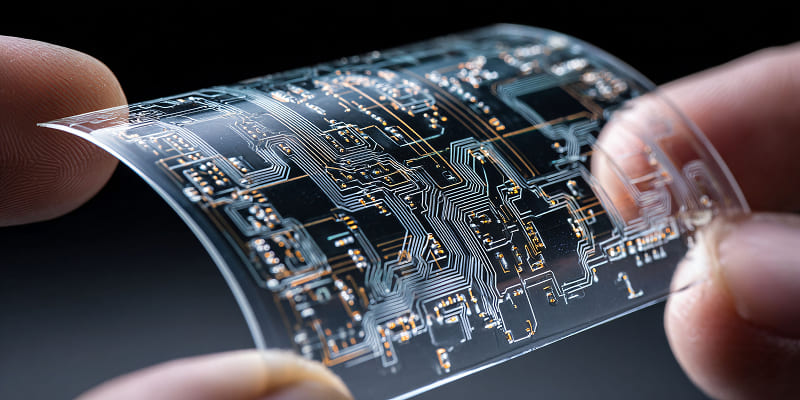

Coatable/printable Dielectric Curable Fluids (Inks)

In a project funded by the FlexTech consortium (part of SEMI) we are maturing technology for a dielectric ink for printed electronics for harsh environments (e.g., aerospace).Currently, there exists many conductive printable inks but few commercial dielectric inks. Existing dielectric inks are not ideal with respect to one or more of the required properties:

- Ultra-low loss tangent extending to high (4/5G) frequencies up to and over 40 GHz, with high dielectric breakdown strength and a low, stable dielectric constant

- Low cure temperature compatible with printed and flexible electronics materials

- Good adhesion to required substrates such as Kapton, PET, and copper

- Controllable and stable viscosity for use in multiple printing and coating methods, including screen printing, aerosol jet, syringe dispense, spray coating, inkjet, and curtain coating at low feature sizes (<50 µm)

- Adequate pot life, suitable storage conditions, and cost effectiveness.

We started this 18 month project in April 2025 with a university partner that initially developed the material and two industry subcontractors.The material is a thermally-cured very low loss ‘ink’ that can be printed at high resolution by commercially-available printers (2D and 3D) for the insulating parts of electronics components and assemblies.The material has potential application as an RF-transparent protective encapsulant for antennae and as solder mask material and for use in multi-layer circuit fabrication.Objects of the development project are to produce versions of the ink with either high or low and stable viscosity for printing and coating by different methods and to characterize and optimize its harsh environment capability (temperature, vibration and shock, radiation, etc.).It will be scalable for electronics printing.Applications will include aerospace electronics, automotive electronics, biosensors, flexible electronics, heaters, keyboard membranes, smart windows, solar cells including organic photovoltaics, touch screens, and wearable electronics.